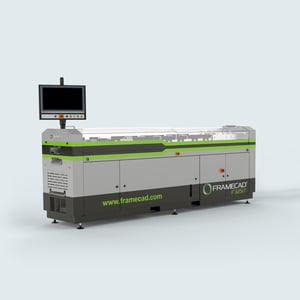

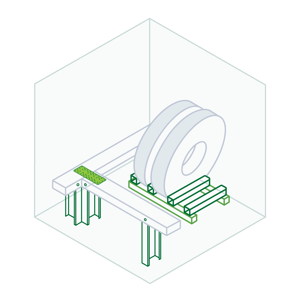

Roll Forming Steel Framing Machines

Your projects demand accuracy, reliability and high productivity. You can rely on our solutions to simplify the building process, ensuring high standards with minimal manual intervention. Advance your business with our steel framing solutions, and framework, to deliver consistent results for your clients through a streamlined building process.

Precision

Steel frames are crafted with precision to guarantee accurate, consistent results in every project, delivering exceptional performance and reliability.

Efficiency and Speed

Complete projects on time and within budget with our high-speed, automated construction equipment. Designed to minimize manual labor and maximize output, our steel framing machines boost your project's efficiency.

Versatility and Flexibility

No matter what your project requires, our roll forming machines and versatile equipment lets you take on a wide range of projects. From residential to commercial construction, interior to exterior, our light gauge steel framing machines meet all your construction needs with confidence.

Manufacturing Process Matched to What You Want to Build

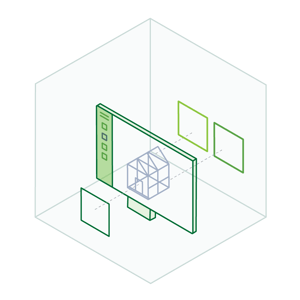

Production Management

With our roll-forming equipment, you benefit from the world's first production management platform for steel framing. You will have complete visibility and control of your operations with quality control, capacity management, and real-time project data so you can build trust and confidence between contractors and customers.

Helping Customers in Over 100 Countries for Over 35 Years

Intellistructure specializes in providing innovative steel framing and structural components to the East Coast of the US.

Accurate Steel Fab manufactures pre-panelized steel components for residential and commercial sectors across Texas.

Do-it-yourselfers are buying steel framing house kits from Frame Up Now and constructing their own house framing onsite.

USG LATAM is reshaping the construction industry across Latin America.

Orlando Steel Framing sees time-saving as one of the biggest advantages of steel framing.

ICS engineers, designs and manufactures prefabricated buildings across the US.

Intellisteel offers a comprehensive range of services that extend from turnkey modular solutions to off-site and on-site applications.

Intellistructure specializes in providing innovative steel framing and structural components to the East Coast of the US.

Accurate Steel Fab manufactures pre-panelized steel components for residential and commercial sectors across Texas.

Do-it-yourselfers are buying steel framing house kits from Frame Up Now and constructing their own house framing onsite.

USG LATAM is reshaping the construction industry across Latin America.

Orlando Steel Framing sees time-saving as one of the biggest advantages of steel framing.

ICS engineers, designs and manufactures prefabricated buildings across the US.

Side-by-Side and End-to-End

Access training modules and tutorials to enhance your team's knowledge and skills on the FRAMECAD Solution.

Customer Success experts are available around the clock to support you whenever your business is operating.

Your one-stop portal for support, Nexa, the Knowledge Center, shop, and training videos.

Have a question for our team? We can walk you through it.

Your one-stop shop with end-to-end solutions to run your business, better.

Design, Manufacture, Build and Deliver All the Way to the Jobsite

The Latest Insights and Trends in Construction Technology

Ready to Reframe How You Build?